Poles and Towers of Transmission Lines

Poles and towers serve as the primary support structures for transmission lines, holding the conductors at the necessary height above the ground. The elevated position of the structure minimizes the risk of interference contributing to the overall safety and reliability of the transmission system.

Poles and towers play a crucial role in managing the spans between transmission and distribution lines. Poles and towers are designed to withstand various environmental conditions such as wind, ice, and seismic activity.

The purpose of line supports is

- To support the transmission and distribution line conductors

- To create a specific distance to the earth

- To provide an equal distance between the conductor

Requirements of Line Supports

- line support must be mechanically strong.

- The total cost of line structure must be minimal.

- The line support weight must be light.

- line supports required less maintenance work.

- The installation of line conductors must be easy on Line supports.

- It must need to minimum correction time.

- it must be flexible.

- it must be reliable and durable.

- It must tolerate weather conditions.

Different Types OF Poles & Towers

- Wooden Poles

- Tubular Steel Poles

- prestressed Concrete Poles

- Self Support Lattice Type Steel Poles

Wooden Poles

Wooden poles are cylindrical structures made from wood and are commonly used for various construction, agriculture, and distribution applications. In rural and suburban areas, wooden poles are commonly used for distributing electrical power.

Wooden poles are often used to support telephone and power lines. voltage rating of the wooden pole is 22kv. The length span of wooden poles is 150 meters. when we install a wooden pole we use a protective compound in its base which is supported when any worn or torn occur.

|

| Wooden poles and towers |

Advantages of wooden poles

- Less Expensive

- Simple Structure

- naturally available

- wooden poles are made with insulating material

- wooden poles are flexible and elastic

- Wooden poles are strong.

Disadvantages of wooden poles

- At ground level, the reaction occurs which leads to wear and tear.

- The lifetime of wooden poles is at most 25 years.

- The voltage limitation is not more than 22kv.

- Wooden poles require proper maintenance at a regular interval distance.

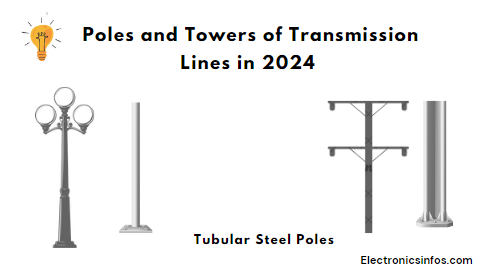

Tubular Steel Poles

A tubular steel pole is constructed in a circular form. The material used in the tubular pole is steel. We used steel Materials because of their high mechanical strength and protection against corrosion. The lifetime of tubular steel poles is much greater compared to wooden poles.

|

| Tubular Steel Poles 2024 |

Tubular steel poles are used in developed areas Because of their high mechanical strength and good appearance. The Lifetime of a Tubular steel pole is also increased if we use galvanized or painted it. Tubular steel poles are manufactured in different sizes and loads as per needs.

At the top of the pole, a cap is used to avoid the entrance of water into the pole. The height of this type of pole is 4-14 meters. Tubular steel poles are manufactured in different shapes like stepped poles, octagonal, high mast, round and decorative etc

Types of tubular steel poles

- Stepped tubular steel poles

- swaged tubular steel poles

Advantages of tubular steel poles

- The lifespan of tubular steel poles is up to 50 years.

- Steel poles are mechanically strong.

- we also increase their span due to mechanical strength

- straight, clean and rust-free

- Tubular steel poles are known for their high strength and durability

- tubular steel poles are relatively lightweight compared to some other materials like concrete

- Tubular steel poles can be designed with a sleek.

- Easy transportation and installation.

- steel poles are Environmentally friendly.

Disadvantages of tubular steel poles

- Expensive as compared to wooden poles

- Due to higher thermal conductivity, the Overall temperature is increased.

- The production of steel involves energy-intensive processes and the extraction of raw materials.

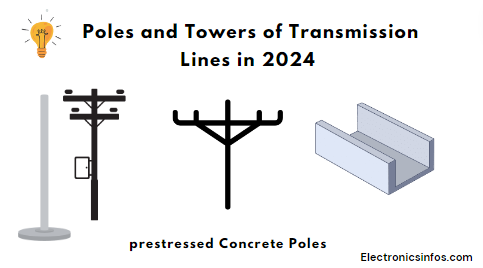

prestressed Concrete Poles

Prestressed concrete poles were pioneered by Eugene Freyssinet in the 1930s. it involves preloading the concrete to induce stresses that counteract the stresses that occur during service.

This process results in concrete that is always in compression, which minimizes the risk of cracking and damage due to environmental factors.

|

| Prestressed Concrete Poles 2024 |

Prestressed concrete poles are now widely used for a variety of applications, including supporting power lines, street lighting, and antenna masts.

The bottom size of RCC is 23*23cm to 30*30cm. RCC poles are tapered structures and another name for prestressed poles is R.C.C.

Advantages of Prestressed Concrete Pole

- RCC span is longer in RCC poles.

- RCC poles Require Less Maintenance

- The lifetime of the prestressed pole is more than tubular steel poles.

- RCC poles are crack-free.

- RCC poles are durable

- the mechanical strength is high

- RCC poles required less material for the construction of poles

- RCC poles are low-deflection

- the maintenance cost is low

- RCC poles are tapered

Disadvantages of Prestressed Concrete Pole

- RCC poles require highly dense material

- RCC poles are an Initial heavy cost.

- The labour required to create RCC poles is high and skilled.

- RCC poles are heavyweight.

- transportation costs are high.

Self Support Lattice Type Steel Poles

Self-support lattice-type steel poles are integral to the structural integrity and functionality of various industries. it is particularly used in telecommunications and power transmission.

These poles are designed to be self-supporting, which means they do not require additional wires or structures to maintain their upright position. The lattice structure of these poles is what gives them their strength and durability.

|

| Self-support Lattice steel pole |

it is Made from interconnected steel rods or angles. This design also allows for less material to be used compared to solid-webbed poles, making lattice-type poles a more economical choice without sacrificing performance.

These types of poles are designed in single circuits and double circuits. These types of poles are used up to 500KV.

Advantages of Self-support Lattice Steel Pole

- Mechanical strength is high for self-support poles.

- the lifetime is high in this type of pole as compared to other poles

- the span of the two poles is high

- this is the economic structure

- These types of poles support each other

- Lattices provide high strength-to-weight ratios.

- Self-supporting towers with lattice designs require less ground space compared to other types.

- These structures can be easily scaled up or down.

- Self-supporting lattice towers are commonly used to support antennas.

Disadvantages of Self-support Lattice Steel Pole

- The cost of a self-support pole is high.

- this type of pole requires heavy material

- Heavier construction compared to other types of poles.

How to find the spacing between the conductors?

To find The minimum distance of the verticle side we can use the following formula

- s= distance between the two conductors in metre

- d= sag in meter

- v= voltage in kV

Conclusion

Frequently Asked Questions – FAQs

What are transmission line poles and towers?

What materials are used to construct transmission line poles and towers?

What is the difference between a pole and a tower in transmission line construction?

How are transmission line poles and towers installed?

What are the factors that determine the spacing between poles or towers?

Are there environmental considerations for transmission line poles and towers?

What are the safety standards for transmission lines and towers?

Related Posts

-Electronicsinfos.png)

0 Comments

please do not insert spam links