Planning of Electrical Installation

Planning and designing of electrical installations involve a series of steps to ensure the safety, functionality, and efficiency of the electrical systems within buildings.

This process includes determining the type of electrical supply, calculating load requirements, and selecting appropriate materials and components.

Proper planning and design are crucial for the reliable operation of electrical systems and adherence to safety standards and regulations.

There are some factors which play an important role in designing the electrical system including

Factors of Consideration of Planning

- Selection Of Wiring System

- Division Of Electrical Circuits

- Estimation Of Load

- Selection Of Cable Size

- Current Carrying Capacity

- Voltage Drop

- Minimum cable size

- Selection Of Switch Gear

- Selection Of Fuse

- Availability OF Equipmemts

- Future Load Prediction

- Safety Precautions

- Flexibility

- Installation Design

Selection Of Wiring System

when we plan an electrical system selection of the wiring system is very important. selection of wiring depends upon which type of work is going on i.e. Industries, power plants, substations, domestic, airport, etc.

For example, at the domestic level, we use a better wiring system. if we use betten wiring in our industry where mechanical strength is needed the wiring system collapses so totally depends on the nature of the work.

The selection of a wiring system depends on various factors, such as the type of building, the expected electrical load, the environmental conditions, and the budget.

Here are the types of wiring systems

- Conduit Wiring

- Surface Wiring

- Concealed Wiring

- Trunking Wiring

- Busbar Wiring

|

| wiring Types |

Conduit Wiring

In this wiring system, electrical cables are enclosed in metal or PVC conduits. Conduit wiring provides excellent protection against physical damage, moisture, and fire. It is commonly used in commercial and industrial buildings.

Surface Wiring

Surface wiring is a simple and cost-effective wiring system where cables are mounted on the surface of walls and ceilings. It is easy to install and maintain, but it is not suitable for heavy electrical loads or harsh environmental conditions.

Concealed Wiring

Concealed wiring is a popular wiring system in residential buildings, where electrical cables are hidden inside the walls and ceilings. It provides a neat and clean appearance, but it is difficult to access for repairs or upgrades.

Trunking Wiring

In this wiring system, electrical cables are enclosed in metal or PVC trunking, which is fixed to the surface of walls and ceilings. It is a good compromise between conduit and surface wiring, offering moderate protection and ease of installation.

Busbar Wiring

Busbar wiring is commonly used in high-rise buildings, where a large number of electrical circuits are required. It involves the use of a copper or aluminium busbar, which is mounted on the surface of walls and ceilings, and electrical connections are made using tap-off units.

Division Of Electrical Circuits

The division of electrical circuits is an important aspect of electrical design and installation. The primary purpose of dividing electrical circuits is to ensure safety, distribute loads evenly, and simplify maintenance and repairs.Here are ways to divide electrical circuits

Function

Electrical circuits can be divided based on their function, such as lighting circuits, power circuits, HVAC circuits, and so on. This helps to simplify troubleshooting and maintenance.

Location

Electrical circuits can be divided based on their location, such as circuits for different floors, rooms, or zones. This helps to distribute loads evenly and prevent overload on any one circuit.

Load Capacity

Electrical circuits can be divided based on their load capacity, such as circuits for high-power appliances, motors, or equipment. This ensures that the electrical system can handle the load and reduces the risk of overload.

Supply Voltage

Electrical circuits can be divided based on their voltage, such as circuits for low-voltage lighting, high-voltage equipment, or medium-voltage distribution. This ensures that the electrical components are compatible and reduces the risk of damage or failure.

Complexity

Electrical circuits can be divided based on their complexities such as circuits for emergency lighting, fire alarm systems, or medical equipment. This ensures that these systems are always operational, even during power outages or faults.

Estimation Of Load

Estimating the electrical load is an important step in designing and installing an electrical system. The load estimation involves calculating the expected electrical demand in terms of power (Watts) or current (Amperes) for all the electrical equipment and devices that will be connected to the system.

Here are steps for estimating the load

- Identify the Electrical Equipment

- Determine the Power Rating

- Calculate the Total Load

- Consider Diversity Factors

- Add a Safety Margin

- Check Compliance with Electrical Codes

Identify the Electrical Equipment

Make a list of all the electrical equipment and devices that will be connected to the system, including lights, appliances, HVAC systems, and motors.

Determine the Power Rating

Determine the power rating (in watts or kilowatts) for each piece of equipment. This information can be found on the equipment label or in the manufacturer's specifications.

Calculate the Total Load

Add up the power ratings for all the equipment to calculate the total load. This will give you an estimate of the total power demand for the system.Consider Diversity Factors

In practice, not all equipment will be operating at full capacity at the same time. Therefore, it is important to consider diversity factors that account for the likelihood of simultaneous use. This helps to avoid overloading the system and reduces the risk of tripping breakers or fuses.

Add a Safety Margin

It is recommended to add a safety margin of 20-25% to the calculated load to account for unexpected increases in demand or future expansions of the system.

Check Compliance with Electrical Codes

Ensure that the estimated load does not exceed the maximum load capacity allowed by local electrical codes and regulations.

Selection Of Cable Size

The cable size is determined by the amount of electrical current it can carry without overheating and causing damage or fire.Here are steps for selecting the cable size

- Determine the Load Current

- Determine the Circuit Length

- Select the Conductor Material

- Calculate the Voltage Drop

- Refer to Cable Sizing Tables

- Consider Safety Factors

Determine the Load Current

The load current is the amount of electrical current that will flow through the cable. It can be calculated using the estimated electrical load and the voltage of the system (I=P/V).

Determine the Circuit Length

The length of the cable run is important in determining the resistance of the cable, which affects the current-carrying capacity. The longer the cable, the higher the resistance and the lower the current-carrying capacity.Select the Conductor Material

Copper and aluminium are the most common conductor materials for electrical cables. Copper is a better conductor but is more expensive than aluminium. The material selected should be appropriate for the specific application and budget.Calculate the Voltage Drop

The voltage drop is the amount of voltage lost due to the resistance of the cable. It is important to ensure that the voltage drop is within acceptable limits to maintain the efficiency and performance of the electrical system. The voltage drop can be calculated using a formula or an online calculator.

Refer to Cable Sizing Tables

Cable sizing tables provide information on the maximum current-carrying capacity of different cable sizes based on the conductor material, circuit length, and voltage drop. These tables are available in electrical codes and standards, manufacturer's specifications, or online resources.Consider Safety Factors

It is recommended to select a cable size that is larger than the calculated current-carrying capacity to account for safety factors such as ambient temperature, cable insulation, and future expansions.Current Carrying Capacity

Find the subcircuit load and final sub-circuit load to calculate the current carrying capacity of the loadVoltage Drop

Accurate voltage drop calculations are a fundamental part of the electrical design to achieve a secure environment.

If not properly accounted for, it can lead to issues such as overheating of cables, which may cause damage or even fire risks. Therefore, it's essential to calculate and minimize voltage drop to prevent power loss and ensure that equipment operates within its designed voltage range.

Minimum cable size

In the power circuit, we normally use 7/0.29'', and for the lightning load we use 3/0.29''.Selection Of Switch Gear

Switchgear is a critical component of an electrical system that helps to protect, control, and isolate electrical circuits. The selection of switchgear depends on several factors, including the voltage level, current rating, switching capacity, and application requirements.

Here are steps for selecting switchgear

- Determine the System Voltage

- Determine the Current Rating

- Determine the Switching Capacity

- Consider the Application Requirements

- Check Compliance with Electrical Codes

- Consider Maintenance and Repair

|

| Selection of switchgear |

Determine the System Voltage

Switchgear is designed for specific voltage levels, such as low voltage (LV), medium voltage (MV), or high voltage (HV). The system voltage is an important factor in selecting the appropriate switchgear.

Determine the Current Rating

The current rating is the maximum amount of electrical current that the switchgear can handle safely. It depends on the size and capacity of the electrical load and is usually expressed in amperes (A).

Determine the Switching Capacity

The switching capacity refers to the ability of the switchgear to interrupt or isolate electrical circuits safely. It depends on the type of fault that may occur and is usually expressed in kiloampere (kA).

Consider the Application Requirements

Switchgear can be customized to meet specific application requirements, such as indoor or outdoor installation, single or multi-bay configuration, manual or automatic operation, and so on.

Check Compliance with Electrical Codes

Ensure that the selected switchgear meets the requirements of local electrical codes and regulations.

Consider Maintenance and Repair

Switchgear requires periodic maintenance and repair to ensure proper operation and safety. It is important to select switchgear that is easy to maintain and repair, with readily available spare parts and technical support.

Selection Of Fuse

Fuses are an important component of an electrical system that protects electrical equipment from overcurrents and short circuits. The selection of fuses depends on several factors, including the rated voltage, rated current, interrupting rating, and application requirements.

- Determine the Rated Voltage

- Determine the Rated Current

- Determine the Interrupting Rating

- Select the Fuse Type

- Check Compliance with Electrical Codes

- Consider Maintenance and Replacement

|

| Selection of fuse |

Determine the Rated Voltage

Fuses are designed for specific voltage levels, such as low voltage (LV) or high voltage (HV). The rated voltage is an important factor in selecting the appropriate fuse.

Determine the Rated Current

The rated current is the maximum amount of electrical current that the fuse can handle safely. It depends on the size and capacity of the electrical load and is usually expressed in amperes (A).

Determine the Interrupting Rating

The interrupting rating refers to the ability of the fuse to interrupt or isolate electrical circuits safely. It depends on the type of fault that may occur and is usually expressed in kiloampere (kA).

Select the Fuse Type

Fuses come in different types, such as fast-acting, time-delay, dual-element, and high-breaking capacity (HBC). The selection of the fuse type depends on the specific application requirements.

Check Compliance with Electrical Codes

Ensure that the selected fuses meet the requirements of local electrical codes and regulations.

Consider Maintenance and Replacement

Fuses require periodic maintenance and replacement to ensure proper operation and safety. It is important to select fuses that are easy to replace, with readily available spare parts and technical support.

Availability OF Equipmemts

The availability of equipment is an important consideration when planning and designing an electrical system. The availability of equipment refers to the ability of the equipment to operate reliably and consistently over a given period, without experiencing failures or downtime.

When selecting equipment for an electrical system, it is important to consider the availability of the equipment in terms of its reliability, maintainability, and repairability.Here are steps for ensuring the availability of equipment

- Select Reliable Equipment

- Consider Maintenance Requirements

- Plan for Maintenance and Repair

- Use Standardized Equipment

- Use Remote Monitoring

|

| Availability of equipments |

Select Reliable Equipment

Choose equipment that is known for its reliability, such as from reputable manufacturers with a proven track record of producing high-quality equipment.

Consider Maintenance Requirements

Evaluate the maintenance requirements of the equipment, including the frequency of maintenance and the level of expertise required to perform maintenance tasks.

Plan for Maintenance and Repair

Develop a maintenance plan that includes regular inspections, preventive maintenance, and repair procedures to ensure that equipment is kept in good working condition.

Use Standardized Equipment

Choose standardized equipment where possible to reduce the complexity of the system and make it easier to maintain and repair.

Use Remote Monitoring

Implement remote monitoring systems for critical equipment to detect potential failures before they occur and to enable prompt action to prevent downtime.

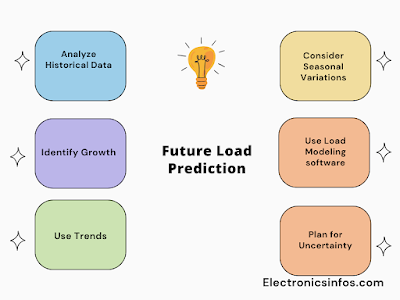

Future Load Prediction

when we plan a system we must focus on present plus future extensions so that according to the future load value, we create a stable system.

Predicting future load is important for designing and planning an electrical system that can meet the future electricity demand. Future load prediction involves analyzing historical data, trends, and projections to estimate the future electrical load.Here are steps for predicting future load

- Analyze Historical Data

- Identify Growth

- Use Trends

- Consider Seasonal Variations

- Use Load Modeling software

- Plan for Uncertainty

Analyze Historical Data

Analyze historical data on electricity consumption to identify trends and patterns in load growth over time. This data can be obtained from electricity bills, meter readings, or energy management systems.

Identify Growth

Identify the drivers of load growth, such as population growth, economic development, industrial expansion, and changes in consumer behaviour.

Use Trends

Use projections from reliable sources, such as government agencies, industry associations, and energy experts, to estimate future trends in electricity consumption. These projections may be based on demographic trends, economic forecasts, or energy policies.

Consider Seasonal Variations

Consider seasonal variations in load, such as increased demand for air conditioning during hot summers or heating during cold winters.

Use Load Modelling software

Use load modelling software to simulate future load under different scenarios, such as changes in customer behaviour, energy efficiency measures, or adoption of new technologies.

Plan for Uncertainty

Account for uncertainties in load prediction by using a range of scenarios, sensitivity analysis, and contingency plans.

Safety Precautions

the safety factor is an important part of the planning of an electrical system. we must follow national electrical safety rules.

Safety precautions are critical when working with electricity to prevent accidents, injuries, and fatalities. Electrical hazards include electrical shock, burns, electrocution, and arc flash.Here are steps for Safety Precautions

- Use Personal Protective Equipment

- De-energize Equipment

- Conduct Regular Maintenance

- Follow Electrical Codes and Standards

- Properly Ground Equipment

- Use Proper Tools

- Avoid Water and Moisture

- Properly Label Equipment

- Use Lockout/Tagout Procedures

- Training and Certification

Use Personal Protective Equipment

De-energize Equipment

Conduct Regular Maintenance

Conduct regular maintenance and inspections of electrical equipment to identify and correct potential hazards.

Follow Electrical Codes and Standards

Properly Ground Equipment

Use Proper Tools

Avoid Water and Moisture

Properly Label Equipment

Use Lockout/Tagout Procedures

Training and Certification

Flexibility

Flexibility is an essential characteristic of an electrical system, which refers to the ability of the system to adapt to changing conditions and requirements. A flexible electrical system can accommodate changes in load demand, the addition of new equipment, changes in operating conditions, and the integration of renewable energy sources.

Here are ways to create flexibility in an electrical system

- Load Flexibility

- Generation Flexibility

- Transmission and Distribution Flexibility

- Interconnection Flexibility

- Planning and Design Flexibility

Load Flexibility

A flexible electrical system can accommodate changes in load demand and can adjust to meet the changing needs of customers. This can be achieved by implementing demand response programs, energy storage systems, and flexible generation resources.

Generation Flexibility

A flexible electrical system can accommodate changes in generation resources and can adjust to match the output of renewable energy sources, such as wind and solar power. This can be achieved by using energy storage systems, flexible gas-fired power plants, and other flexible generation resources.

Transmission and Distribution Flexibility

A flexible electrical system can accommodate changes in transmission and distribution infrastructure and can adjust to changing operating conditions. This can be achieved by implementing advanced control systems, automation, and intelligent switching devices.

Interconnection Flexibility

A flexible electrical system can accommodate changes in interconnection between different electrical systems and can adjust to changes in energy flows. This can be achieved by using advanced control systems and communication technologies to coordinate the operation of interconnected systems.

Planning and Design Flexibility

A flexible electrical system can accommodate changes in the planning and design of the electrical system and can adjust to changing requirements. This can be achieved by using modular and scalable designs, flexible equipment specifications, and flexible procurement strategies.

Complete Installation Design

we prepare a complete installation design that shows each measurement, locations of equipment, their arrangements, and also safety precautions, in this wiring diagram we clearly divide the wiring into lightning wiring diagrams and power wiring diagrams. they must contain the following diagram

- Schematic wiring diagram

- single line diagram

- isometric and other sketches

- detailed diagram and equipment schedules

Steps involved in designing a complete electrical installation

- Site Assessment

- Load Estimation

- Selection of Equipment

- Cable Sizing

- Circuit Design

- System Control and Monitoring

- Documentation and Testing

Determination of the number of lamps

Determination of the number of lamp is important for the proper function of an electrical circuit. The exact requirements for the Number of lamps also depend on the nature of the work.

For example, we need normal light for domestic purposes we use a 100-watt lamp. the final subcircuit current rating is 5 A and the supply voltage is 230 v.the maximum no of lamps we need is

Conclusion

In conclusion, planning and designing electrical installations is a complex process that requires careful consideration of various factors to ensure safety, functionality, and efficiency. It involves understanding the supply type, load requirements, and safety measures.

The installation must comply with regulations and standards and should be carried out by qualified professionals. Ultimately, a well-planned electrical installation can significantly contribute to the operational success of a building or facility.

Frequently Asked Questions – FAQs

What are the steps in receiving and distributing the main supply?

- Installation of a circuit breaker or load break switch fuse on each live conductor at the point of entry.

- Ensure no switch or fuse is placed in the earthed neutral conductor and that the main switch is easily accessible.

Where should energy meters be installed?

In residential buildings, meters should be placed where they are easily accessible for reading and maintenance, preferably above 1 meter from the ground.

What safety precautions are necessary during installation?

Work with a qualified electrician, use the correct tools and equipment, and adhere to safety procedures to prevent common electrical installation issues.

Related Posts

-Electronicsinfos.png)

0 Comments

please do not insert spam links