Here is what we cover

what is a Cable?

A Conductor is used to transmit electrical energy, whether is bare or insulated called a cable. Cables are essential components in various industries, connecting devices, systems, and networks. They come in different types based on their design, materials, and applications. There are many types of cables available for example Power cables, Control cables, fibre optics cables, communication cables, coaxial cables etc

|

| Types of cables |

Properties of Cables

- High electrical conductivity reduces energy losses as electricity travels through the cable.

- Insulation ensures safety by avoiding short circuits and protecting against electric shocks.

- Mechanical strength is essential for the durability and reliability of cables, especially in applications involving mechanical stress.

- Thermal resistance ensures that cables can operate in environments with elevated temperatures without degradation. It contributes to the longevity and reliability of the cable.

- Chemical resistance protects cables from damage in environments where exposure to corrosive substances is likely.

- Effective shielding is essential for preventing electromagnetic interference (EMI) or radio-frequency interference (RFI), which can degrade signal quality.

- Environmental resistance ensures that cables can withstand exposure to elements like moisture, sunlight, and UV radiation.

- Matching impedance is essential for optimizing signal transmission in communication cables.

- Fire-resistant cables enhance safety in buildings and critical infrastructure.

In this article, we discuss the comparison of the Overhead system and the underground system of the electrical system.

underground cables

- underground cables are protected from the lightning effect

- the fault level of underground cable is low

- Fault tracking is difficult in underground cables

- the maintenance cost plus fault tracking cost is high

- the possibility of a public accident is low

- bunching of underground cables is difficult.

- bunching cost of cable is high

- its appearance is good

- underground cable not interference in communication lines

- the inductive voltage is less as compared to others.

- not interfere in road crossing

- underground cables are not used for long-distance

- we use underground cables in Populated Areas

- underground cable is the most reliable and protected

- we use underground cables for low voltage to extra high voltages.

- the current carrying capacity is low

- underground cables have low inductance reactance

- the capacitive reactance of underground cable is high

- the lifetime of underground cables is long.

- tappings are difficult in underground cables.

overhead lines

- overhead lines are not protected from the lightning effect

- the fault level of overhead lines is higher as compared to underground cables

- fault tracking is easy in overhead lines

- the maintenance cost of overhead lines is low compared to underground cables

- the chance of a public accident is greater as compared to underground cables.

- the installation of overhead lines is easy compared to the underground system.

- this is low cost as compared to the underground system

- the appearance is not good compared to the underground system

- overhead lines interfere with communication lines

- the voltage drop of overhead lines is high

- in populated areas, the preference for overhead lines is not used.

- overhead lines system is reliable and durable

- they need more space in terms of line structure

- the current carrying capacity is high

- the inductive reactance of the overhead system is high

- overhead lines system used low voltage to extra high voltage

- the capacitance reactance of the overhead system is low

- the working life of the overhead system is low compared to the underground system

- the voltage drop is high in overhead lines.

- the installation cost of this system is low compared to the underground system.

Types of cables

There are three types of cables including

- Types of cables concerning the core

- Types of cables concerning voltage

- Types of cables concerning insulation

w.r.t Core

There are two types of cables, the first is single-core and another one is three-core

- Single-core cable

- three core cable

Single-core cable

A single-core cable is made with a stranded conductor which consists of a circular form. we use impregnated insulation I the top of the conductor then we circulate the lead sheath at the insulating. material. this lead sheath protects the insulation from humidity.in internal generating stations we used plain lead core cable.to protect from corrosion we use that tape as an insulating material.to reduce the eddy current losses we do not use armouring at the single-core cable.

|

| single-core cable |

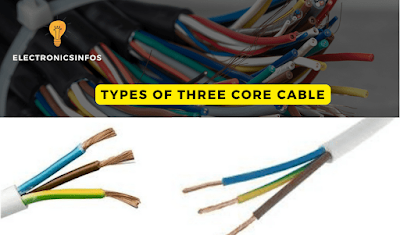

Three core cable

Three core cables consist of the multi-core is called three core cable. we put three conductors or three cores in a single lead sheath.to protect the three core cables we used steel armouring. we used a three-phase cable to transmit the electrical energy.to consider the economic condition we use three core cables at a voltage level of 66kv. if we increase the voltage above 66kv the cable length and size of the cable are increased.

|

Three core cable |

Types of cables W.r.t voltages

- Low tension cables

- High tension cables

- Super tension cables

- Extra high-voltage cables

Low tension Cables

low tension cables are defined as those that are used up to 1000 voltages. Low-tension cables are typically constructed with copper or aluminium conductors, and insulated with materials like PVC (polyvinyl chloride) or XLPE (cross-linked polyethene).

|

| Low Tension Cable |

Low-tension cables, often referred to as low-voltage cables, play a crucial role in electrical systems, providing a safe and reliable means for transmitting power and signals in various applications. Here's an overview of low-tension cables: Low-tension cables form the backbone of electrical infrastructure in countless applications, contributing to the safe and efficient distribution of power and signals.

Low-tension cables find extensive use in a variety of applications, including residential, commercial, and industrial settings. Some common applications include:

- Power distribution within buildings.

- Wiring for lighting systems.

- Electrical installations in homes and offices.

- Connection of electrical devices and appliances.

- Low-power equipment and machinery.

High-tension cables up to 11 kV

High-tension cables, also known as high-voltage cables, are specialized electrical cables designed to transmit electricity at voltages higher than standard residential or commercial voltages. These cables are essential for long-distance power transmission, connecting substations, and distributing electricity across large areas.

|

| High Tension Cables |

High-tension cables up to 11 kV are commonly used in

- Medium voltage power distribution systems.

- Connecting electrical substations to transmit power over long distances.

- Industrial applications require higher voltage levels for machinery and equipment.

High-tension cables typically have copper or aluminium conductors, insulated with materials like XLPE, EPR (ethylene propylene rubber), or paper.

Super tension cables 22kv to 33 kV

High-tension cables operating within the voltage range of 22 kV to 33 kV. Supertension cables are commonly used for transmitting electrical power from power generation stations to distribution substations. They are also employed in the secondary distribution network to supply power to industrial areas, commercial zones, and densely populated regions. Copper or aluminium conductors are often used, due to good electrical conductivity and mechanical strength.

There are Three Types of super-tension cables including

- H-type cables

- S.L type cables

- H.S.L type cables

Extra-High voltage cables

Extra-high voltage cables typically operate at voltage levels beyond 33 kV, reaching up to and beyond 345 kV. Extra-high voltage (EHV) cables are a specialized category of power cables designed to transmit electricity at extremely high voltage levels. These cables are a critical component of electrical power systems, enabling the efficient and long-distance transmission of electricity from power generation sources to distribution networks.

|

| Extra-high voltage cables |

- Extra high-voltage cables are used in Long-Distance Power Transmission and Grid Integration.

- EHV cables may be used in submarine applications to connect offshore wind farms or island power systems to the mainland grid.

- Extra-high voltage is transmitted through overhead lines supported by tall towers.

Conclusions

Frequently Asked Questions – FAQs

What are the main advantages of overhead lines?

Are underground cables more expensive than overhead lines?

What factors should be considered when deciding between overhead and underground transmission systems?

What is the difference between power cables and communication cables?

What are the common uses of power cables in electrical systems?

Related Posts

-Electronicsinfos.png)

0 Comments

please do not insert spam links