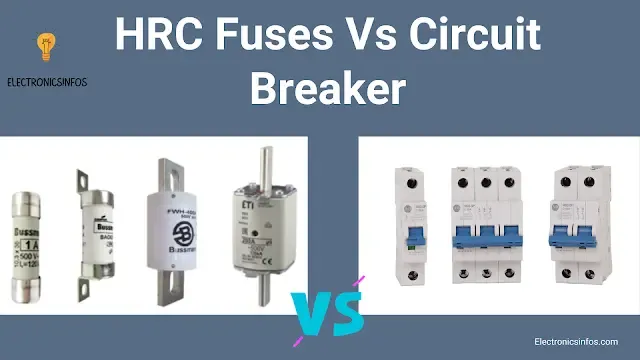

Comparison of HRC Fuses and Circuit Breaker

What is HRC Fuse?

HRC Fuse is a High Rupturing Capacity Fuse that protects the System from faults.

Ratings of HRC Fuse

- Voltage Rating

- Current Rating

- Interrupting Rating

- Time-Current Characteristics

- Operating Temperature Rating

- UL Rating

Voltage Rating

This indicates the maximum voltage that the fuse can safely handle.

- Low Voltage Fuses: Up to 600V AC or DC

- Medium Voltage Fuses: 601V to 15,000V AC or DC,

- High Voltage Fuses: Above 15,000V AC or DC

For example, if you have a circuit operating at 240 volts, you should use a fuse with a voltage rating of at least 240 volts. It's often a good practice to choose a fuse with a slightly higher voltage rating than the circuit's nominal voltage to provide a safety margin.

Current Rating (Ampere Rating)

This indicates the maximum current that can flow through the fuse without causing it to blow.

- Miniature Fuses: 0.5A to 30A

- General-Purpose Fuses: 1A to 600A

- High Current Fuses: above 601A

Interrupting Rating

Interrupting rating is Also known as breaking capacity. This rating signifies the maximum fault current that a fuse can safely interrupt without causing damage.

- Low Interrupting Rating Fuses

- High Interrupting Rating Fuses

Time-Current Characteristics

Fuses have specific time-current characteristics, such as fast-acting (quick-blow) or slow-blow.

Fast-Acting (Quick-Blow) Fuses

it Respond quickly to overcurrents that are suitable for protecting sensitive electronic components.

Slow-Blow Fuses

It tolerates temporary overloads before blowing that are used in circuits with inrush currents or motor starting.

Operating Temperature Rating

Indicates the range of temperatures within which the fuse can operate effectively without derating or malfunctioning.

- Standard Temperature Fuses: Typically rated for temperatures up to 125°C.

- High-Temperature Fuses: with ratings exceeding 125°C.

UL Rating

In North America, fuses may carry Underwriters Laboratories (UL) ratings, which certify their compliance with safety standards.

IEC Rating

In international standards, fuses may have International Electrotechnical Commission (IEC) ratings, providing similar information about their voltage, current, and breaking capacity.

Construction Of HRC Fuse

HRC (High Rupturing Capacity) fuses are designed to handle high fault currents safely. There are different parts including

- Fuse Element

- Fuse Body

- End Caps

- Arc-Quenching Material

Fuse Element

The core component of an HRC fuse is the fuse element, typically made of a high-conductivity metal like silver or copper.

The element is designed to melt and break the circuit when subjected to excessive current, thus protecting the circuit from damage.

- Silver: Known for its high conductivity and low melting point, making it suitable for quick response to overcurrent conditions.

- Copper: Also highly conductive, used in some HRC fuse elements for its excellent electrical properties.

Fuse Body

The fuse body houses the fuse element and provides mechanical support and insulation.

It is often made of ceramic or fibreglass-reinforced plastic to withstand high temperatures and mechanical stress.

- Ceramic: Offers excellent thermal and electrical insulation properties, often used for HRC fuse bodies to withstand high temperatures during fault conditions.

- Fiberglass-Reinforced Plastic (FRP): Provides a combination of strength, insulation, and heat resistance, commonly used in modern HRC fuse designs.

End Caps

HRC fuses have end caps at each end of the fuse body. These end caps are usually made of brass or another conductive material to provide electrical connections to the circuit.

- Brass: Offers good conductivity and corrosion resistance, used for the end caps of HRC fuses to provide electrical connections.

- Copper: In some cases, copper end caps may be used, especially in high-current HRC fuses.

Arc-Quenching Material

Inside the fuse body, there may be arc-quenching materials such as quartz sand or boric acid. These materials help extinguish the arc that forms when the fuse element melts, preventing sustained arcing and protecting the surrounding equipment.

- Quartz Sand: Used as an arc-quenching medium inside HRC fuses to extinguish electrical arcs quickly and efficiently.

- Boric Acid: Another arc-quenching material that helps suppress arcing when the fuse element melts.

HRC Fuses

- HRC Fuses possess higher rupturing Capacity in the medium voltage Range. Fuses Of Rupturing Capacity is 75 MVA are available.

- HRC Fuses are Cheaper.

- HRC fuses take up less space.

- HRC Fuses are Simple to Install and Maintain.

- In the case of Severe Faults, the HRC Fuse opens a circuit in less than half a cycle.

- There is no deterioration in the case of HRC fuses.

- Less Maintenance except periodic tightening of connection.

- Extreme Reliability

- Coordination and discrimination to a high degree.

- Closer Control on sustained overloads due to low fusing factor and the time lag feature.

- Current Limitation by Cut-off Property. During severe faults, an HRC fuse opens the circuit before the peak of the prospective fault current is reached, thus protecting the equipment against maximum thermal and dynamic stress.

What is a Circuit Breaker?

A circuit breaker is a mechanical switching device designed to automatically open a circuit under specified abnormal conditions without injury to itself.

Ratings of Circuit breaker

- Voltage Rating

- Current Rating (Ampere Rating)

- Interrupting Capacity (Breaking Capacity)

- Trip Curve

- Short-Time Withstand Rating

- Overload Rating

- Insulation Voltage

- Rated Frequency

- Service Short-Circuit Breaking Capacity (Ics)

- Ultimate Breaking Capacity (Icu)

Voltage Rating

Current Rating (Ampere Rating)

Interrupting Capacity (Breaking Capacity)

Trip Curve

Short-Time Withstand Rating

Overload Rating

Insulation Voltage (Ui)

Rated Frequency

Service Short-Circuit Breaking Capacity (Ics)

Ultimate Breaking Capacity (Icu)

Circuit Breaker

- Circuit breakers possess lower and too bulky rupturing Capacity in the medium voltage Range. The Minimum rupturing capacity is 250MVa for 11 kV and 350MVA for 33 kV is recommended.

- Circuit breakers are expensive compared to fuses.

- Circuit breakers take up more space compared to fuse.

- Circuit breakers are hard to Install and Maintain.

- In the case of Severe Faults, Circuit breakers open a circuit in more than 2-3 cycles.

- Circuit breakers are prone to become sluggish in operation with laps of time. The Worn latches, contacts etc can cause maloperation of the circuit breaker.

- A Circuit breaker may use air or oil as the arc quenching medium and may have one or more poles.

Conclusion

FAQs(Frequently Asked Questions)

What are HRC fuses and how do they work?

What are circuit breakers and how do they function?

Which is more cost-effective: HRC fuses or circuit breakers?

Where are circuit breakers most commonly used?

what are the different types of circuit breakers?

- AC Circuit Breaker

- DC Circuit Breaker

- High Voltage Circuit Breaker

- Low Voltage Circuit Breaker

- Miniature Circuit Breaker (MCB)

- Molded Case Circuit Breaker (MCCB)

- Oil Circuit Breaker

- Air Circuit Breaker

- SF6 Circuit Breaker

- Vacuum Circuit Breaker

- Single Pole Circuit Breaker

- Double Pole Circuit Breaker

What is the difference between MCCB and ACB?

MCCB (Molded Case Circuit Breaker)

- it is used on the load side of the circuit.

- it has a current rating of up to 3200 A.

- MCCB is Suitable for frequent switching operations.

- It offers protection from overload, short circuits, and instantaneous overcurrent.

ACB (Air Circuit Breaker)

- it is used on the upstream side of the circuit.

- It can handle higher current ratings, typically up to 6300 A.

- it is less frequently operated compared to MCCBs.

- it uses air as the arc quenching medium.

What is Elcb? and Where is Elcb used?

ELCB stands for Earth Leakage Circuit Breaker.it is a safety device used to detect and interrupt power supply when electrical currents leak to earth from an installation.

ELCBs are used in residential, commercial, and industrial electrical installations.

What are the Types of ELCB?

- Voltage Earth Leakage Circuit Breakers

- Current Earth Leakage Circuit Breakers

-Electronicsinfos.png)

0 Comments

please do not insert spam links