What are Overhead line Conductors?

overhead line conductors are a crucial component for the transmission and distribution of electricity. overhead lines conductors carrying power from generating stations to substations and then on to consumers.

|

| Overhead Line Conductors |

The Main Structure of the overhead line is the Conductor

- support Structure

- metal hardware

- insulators

Types Of Conductors W.r.t Materials

- Hard Drawn Copper Conductors

- Aluminium Conductor

- Steel Conductors

- Aluminium Alloy Conductors(AAC)

- ALL Aluminium Alloy Conductors(AAAC)

- Copper Weld Conductors(CW)

- Alumo Weld Conductors(AW)

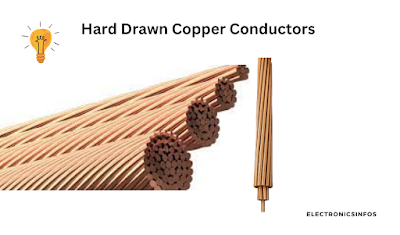

Hard Drawn Copper Conductors

|

| Hard Drawn Copper Conductor |

- its strength and hardness are great.

- Hard-drawn Copper has high mechanical strength.

- Hard-drawn copper has a high resistance to deformation.

- it maintains a degree of flexibility which is important in ease of installation.

- Hard-drawn copper conductors maintain high electrical performance.

- Copper inherently possesses good corrosion resistance, and hard-drawn conductors retain this property.

- Hard-drawn copper conductors are available in various diameters.

- Hard-drawn copper conductors generally maintain good solderability.

Aluminium Conductor

Aluminium conductors are widely used in the power transmission and distribution industry. Aluminium Conductor Steel Reinforced (ACSR) cables, for instance, combine the lightweight and good conductivity of aluminium with the high tensile strength of steel.

This makes ACSR cables a preferred choice for long-distance power lines. Moreover, different variations of aluminium conductors like All Aluminium Conductors (AAC) and All Aluminium Alloy Conductors (AAAC) cater to specific needs, such as in urban areas or regions requiring higher corrosion resistance.

Advantages of Aluminium conductor

- it possesses good electrical conductivity.

- Aluminum is significantly lighter than copper.

- Aluminium is generally more cost-effective than copper.

- Aluminium naturally forms a thin oxide layer on its surface, providing good resistance to corrosion.

- Aluminum is a ductile material, meaning it can be drawn into wires without breaking.

- Aluminum has a higher coefficient of thermal expansion compared to copper.

- Aluminium conductors are commonly used in overhead power lines due to their lightweight nature.

- Aluminum conductors are compatible with various insulation materials.

- Aluminium conductors are used in building wiring for electrical distribution systems.

Steel galvanized Conductors

Galvanized steel is a type of steel that has been coated with a protective layer of zinc to prevent corrosion. The electrical conductivity of galvanized steel is determined by the thickness of the zinc layer.

A thicker layer will result in lower conductivity. The conductivity of steel galvanized at 20 degrees is 12.4% and the density is 7.77 gm/㎤ .Advantages of Steel Galvanized Conductor

- Steel Galvanized makes them well-suited for corrosive environments.

- The galvanized layer adds durability to the steel conductors, protecting them from External factors i.e. weather, moisture, etc

- Steel galvanized coating further improves its resistance to mechanical stress.

- Galvanized steel conductors can withstand a large range of temperatures.

- Galvanized Steel has high tensile strength.

Aluminium Alloy Conductors(AAC)

Aluminium Alloy Conductors, commonly known as AAC. These conductors are made from high-purity aluminium reinforced with other alloys to enhance their strength. AAC is widely used due to its excellent conductivity, low weight, and corrosion resistance.

Advantages of Aluminium Alloy conductor

- Aluminium alloy conductors are lighter than traditional copper conductors.

- Alloying elements, such as magnesium and silicon, enhance the mechanical strength of aluminium alloy conductors.

- The alloying elements contribute to increased corrosion resistance, making aluminium alloy conductors suitable for outdoor applications

- Aluminium alloy conductors maintain good flexibility.

- Aluminium alloy conductors have good thermal stability.

ALL Aluminium Alloy Conductors(AAAC)

All Aluminum Alloy Conductors (AAAC) are a significant type of high-capacity, high-strength stranded conductor used for overhead power lines.

its superior strength-to-weight ratio, which allows for longer spans between support structures. This conductor is made from an aluminium-magnesium-silicon alloy that is lighter in weight.

AAAC is also known for its excellent corrosion resistance, making it a preferred choice in coastal and industrial areas where environmental conditions can be harsh.

Advantages of All Aluminium Alloy Conductor

- AAAC conductors are lightweight.

- The aluminium alloy composition enhances the mechanical strength of AAAC conductors.

- AAAC conductors provide good electrical conductivity.

- AAAC conductors maintain good flexibility,

- AAAC conductors offer a cost-effective solution for overhead transmission and distribution systems.

Alumo Weld Conductors(AW)

Alumoweld conductors are a type of aluminium-clad steel wire used in overhead power lines. They combine the high strength of steel with the excellent conductivity and corrosion resistance of aluminium.

This makes them particularly suitable for long-span electrical transmission lines in corrosive environments, such as coastal areas or industrial zones. Alumo weld conductors are known for their superior strength-to-weight ratio compared to traditional galvanized steel cores.

Advantages of Alumo Weld conductor

- The tensile strength of an alumo weld conductor is equal to a steel conductor

- The density of alumo weld conductor as compared to steel is low

- The corrosion effect of alumo weld is low

- The conductivity of the alumo weld conductor is high

- alumo weld conductor is used in heavy damp and saline areas

- alumo weld conductor is used as overhead earth lines and gay stranded

- alumo welds are also used as medium transmission and telecommunication lines.

Copper Weld Conductors(CW)

Copper Weld Conductors are a type of bimetallic conductor that combines steel's strength and durability with copper's conductivity. These conductors are designed to optimize the use of copper.

Copper Weld Conductors are used in a variety of applications, including power and grounding conductors for building construction, power grids, utilities, communications, and transportation.

Copper weld is also used in transmission and distribution lines. we used steel wire as a conductor and copper as coated material. in comparison to steel wire, there are some advantages of copper weld conductors which are including

Advantages of Copper weld conductor

- Copperweld conductors feature a solid copper layer on the outside, providing excellent electrical conductivity.

- The steel core within Copperweld conductors imparts high mechanical strength.

- The outer layer of copper provides inherent corrosion resistance.

- Copperweld conductors exhibit reduced thermal expansion.

- Copperweld conductors maintain a degree of flexibility.

Types Of Conductors W.r.t Construction

- Solid Conductor

- Hollow Conductor

- Stranded Conductors

- EXpended Conductors

- Stranded And Reinforced Conductors

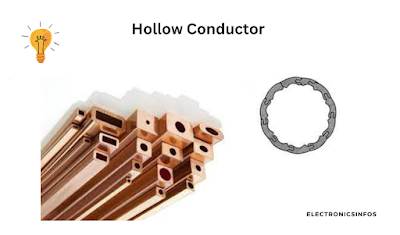

Hollow Conductor

|

| Hollow Conductor |

Advantages Of Hollow Conductor

- A hollow conductor saves the conductor material.

- The cooling effect is better as compared to a solid conductor.

- The current rating capacity of a hollow conductor is high.

- By using the hollow conductor we minimize the corona effect

- It also minimizes the skin effect.

- The system efficiency is also increased by using a hollow conductor.

- Hollow conductors are lighter than solid conductors.

- The hollow core allows for better thermal insulation,

- Hollow conductors often have a higher resonance frequency compared to solid conductors of the same outer diameter.

- Hollow conductors can exhibit lower eddy current losses, especially in high-frequency applications.

- Hollow conductors may be less susceptible to vibrations compared to solid conductors.

- Hollow conductor Reduced Electromagnetic Interference (EMI).

Stranded Conductors

These conductors consist of multiple thin wires, or strands, made of copper or aluminium. it is twisted together to form a single conductor. they are used in electronic devices, vehicles, and industrial machinery.

The form of a stranded conductor gives us two benefits one is the minimum x-section and the second is the low diameter of the conductor.

|

| Stranded Conductor |

Advantages of Stranded Conductor

- The stranded conductor is more flexible as compared to a solid conductor

- On a large scale, the manufacturing of stranded conductors is easy

- we made the long length of the stranded conductor as compared to a solid conductor

- The handling, transporting and installation are easy as compared to the solid conductor

- The stranded conductor also reduced the skin effect

- The possibility of aluminium reinforcement is easy

- The cooling effect of the stranded conductor is easy

- the breaking effect is less as compared to a solid conductor

Expended Conductors

An expanded conductor is the most used conductor in transmission and distribution systems nowadays. The expanded conductor is made with steel-stranded Material and uses some insulating material as a material filler.

On the upper side of the filler, we use aluminium strands to increase the overall diameter that's why we called the expanded conductor.

|

| Expended Conductor |

Advantages of Expanded Conductor

- The skin effect of the expanded conductor is low

- The Corona effect is also low

- The inductance of an expanded conductor is low

- The cooling effect is better in the expanded conductor

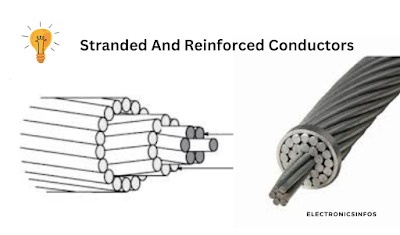

Stranded And Reinforced Conductors

Stranded and reinforced conductors are essential components in the electrical power system.it is frequently used for transmission and distribution lines. A stranded conductor is composed of several thin wires, known as strands.

The stranding process involves twisting the strands in helical layers, with each successive layer typically twisted in the opposite direction to enhance the conductor's structural integrity.

|

| Stranded and Reinforced Conductor |

Advantages of stranded and reinforced Conductor

- Stranded and reinforced conductors are more flexible.

- Mechanical strength of stranded and reinforced conductor

- Stranded & reinforced conductors offer better termination options.

Conclusion

In conclusion, the choice of overhead line conductors is a critical decision in the design and operation of power transmission and distribution systems. Each type of conductor offers unique advantages.

Frequently Asked Questions – FAQs

What are Hard Drawn Copper Conductors?

Hard Drawn Copper Conductors are solid copper wires that undergo a process of drawing to increase their strength and conductivity.

What are the advantages of Hard Drawn Copper Conductors?

They offer high electrical conductivity, excellent corrosion resistance, good mechanical strength, and durability, making them ideal for use in power transmission and distribution systems.

How do Aluminium Conductors compare to copper conductors?

While aluminium has lower conductivity than copper, Aluminium Conductors are preferred for long-distance power transmission due to their lighter weight and lower cost, although they may require larger cross-sections for equivalent performance.

What are the applications of Aluminium Conductors?

They are used in overhead power lines, aerial bundled cables (ABC), and substation connections.

Are there different types of Aluminium Conductors available?

What are Steel Conductors?

Steel Conductors are electrical conductors that incorporate steel wires or strands along with other materials like aluminium or copper.

Are there different configurations of Steel Conductors available?

Yes, Steel Conductors come in various designs such as Aluminium Conductor Steel Reinforced (ACSR), Aluminium Conductor Steel Supported (ACSS), and Aluminium Conductor Composite Core (ACCC).

Where are AAAC conductors commonly used?

They are used in overhead transmission and distribution lines, especially in areas with high mechanical loads, temperature variations, and corrosive environments.

What are Copper Weld Conductors (CW)?

Copper Weld Conductors are electrical conductors made from copper wires or strands that are welded or bonded together to form a continuous conductor.

What are the applications of AW conductors?

AW conductors are used in overhead power lines, electrical grids, renewable energy systems, and industrial settings where lightweight, high-strength conductors with minimal maintenance requirements are needed.

Related Posts

What is a Transformer?

How to Reduce The Transformer Losses?Single Phase Transformer Vs Three Phase Transformer

Transformer Oil Testing

EMF Equation Of Electrical Transformer

3 Types of Electrical Transformers w.r.t Core

What is an Auto Transformer?

Regulations of Electrical Transformer?

-Electronicsinfos.png)

.png)

0 Comments

please do not insert spam links