Exploring the World of Specialized Insulators

Insulators play an important role in the world of electrical engineering. They are materials that resist the flow of electric current.it is an essential component in power transmission and electronic devices.

Among the vast array of insulators, some stand out due to their specialized functions and unique properties. It allows for informed decisions when designing or upgrading power systems, ultimately contributing to the reliability and safety of electrical infrastructure worldwide.

These types of insulators are designed for anti-fog and anti-dirt Environments. The Outer shades of special insulators are also higher as compared to normal insulators. Some types of Special insulators are used in substations to support and drive the Electrical system.

Where we use special insulators

- where the environment is polluted or contaminated

- where overvoltage is more as per normal volatge

- where more electrical stress is occurring

- where the lightning effect frequently occurs

- where natural disasters frequently occur

- special insulators we used where we needed to drive the specific work.

Types OF Special Insulators

- Pin Type Anti-Dirt Insulators

- Inclined Disc Insulators

- Deep Shed Insulators

- Solid Core Insulator

- Aerodynamic Insulators

Pin Type Anti-Dirt Insulators

These insulators are designed to combat the challenges posed by environments with high levels of pollution and dirt. Their unique shape and surface properties help prevent contaminants that can lead to flashovers and power outages.

By repelling dirt and maintaining their insulating properties, these insulators ensure consistent performance in adverse conditions.

pin type anti-dirt insulator is a special type of insulator whose creepage distance is 490mm. The working voltage of this type of insulator is 11kv.

|

| pin type anti-dirt Special insulators |

The shades of this type of insulator are also high so water is easily entering in shades and every type of dirt is removed.. their performance is much better as compared to normal insulators.

Advantages of pin-type anti-dirt insulators

- Mechanical strength is high.

- creepage distance is high around 490mm.

- lifetime is high.

- shades are long.

- anti-ageing performance is high.

- breakdown strength is high.

- tensile strength is high.

- puncture strength is high.

- electrical field distributed uniformly.

Disadvantages pin-type anti-dirt insulators

- The cost of the anti-dirt insulator is high compared to the normal pin-type insulators.

- Pin-type anti-insulator is used for a specific purpose.

- Pin-type dirt insulators have a limited voltage level.

Inclined Disc Insulators

Inclined disc insulators are designed for areas where the angle of the power lines needs to be adjusted. They provide the necessary mechanical strength and electrical insulation.

Inclined disc insulators are particularly useful in mountainous regions or in complex substation configurations. these type of insulators is also called anti-dirt suspension insulators.

when we create a string of this type of insulator we use one insulator on one side and another insulator on another side. the result in an increased voltage level. The length and height of the inclined disc insulator respectively are 279mm and 159mm.

|

| inclined disc-type Special insulator |

Advantages of Inclined Disc Insulators

- Inclined Disc Insulator has high resistivity.

- The dielectric strength of Inclined Disc insulators is high.

- The relative permittivity of Inclined disc material is high.

- The inclined disc insulator has anti-fog and dirt properties.

- Mechanical strength is strong.

Disadvantages of Inclined Disc Insulators

- Inclined Disc Insulator puncture voltage is low.

- inclined disc insulator is not very reliable in specific conditions.

- Cleaning inclined disc insulators to maintain their time-consuming process.

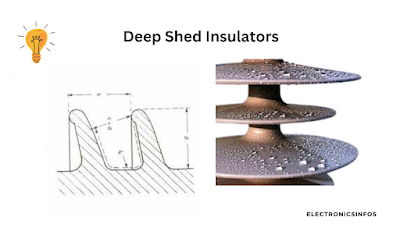

Deep Shed Insulators

Deep shed insulators offer enhanced protection against wet conditions With their extended sheds (the flared part of the insulator). The deeper sheds create a longer leakage path for water.

it is especially beneficial in regions with heavy rainfall or fog. This design helps to prevent electrical discharges and ensures the reliability of power systems. The diameter of the deep shed insulator is 280mm.

|

| Deep Shed Special Insulator |

Advantages of Deep Shed Insulators

- Deep shed insulator mechanical strength is high.

- Their creepage distance is high.

- The leakage path is long.

- it has anti-fog and anti-dirt properties.

- The shed is long in deep shep insulators.

Disadvantages of Deep Shed Insulators

- Deep-shed insulators can pose challenges during maintenance.

- Deep-shed insulators can be more expensive.

- In high pollution or contamination levels, deep-shed insulators may be more prone to surface contamination.

- The extended design of deep-shed insulators requires more space compared to compact or suspension insulators.

- Deep-shed insulators may be more sensitive to vibrations.

- Proper installation can be time-consuming, potentially taking several hours depending on the size of the shed and the complexity of the installation process.

- In humid environments, without a proper vapour barrier, insulation can trap moisture and lead to mould growth and wood rot.

Solid Core Insulator

Solid core insulators are known for their robust construction. They are commonly used in high-voltage applications. They are made from materials that can withstand extreme electrical stress and physical loads.

These insulators are a staple in substations due to their durability and long service life with a working voltage is 33kv.

|

| Solid Core Insulator |

Advantages of Solid Core Insulators

- The solid core insulator has large mechanical strength.

- solid core insulator has a high puncture value.

- Solid core insulators feature anti-ageing, anti-UV, and anti-sandstorm designs.

- Their simplicity and rigidity make them easier to work with during installation, stripping, termination, and insertion into terminal blocks or connectors.

- Solid core insulators have lower electrical resistance compared to other types, which can lead to more efficient power transfer and reduced power loss.

- Solid core insulators are used up to 1100kv.

Disadvantages of Solid core Insulators

- The solid core insulator is expensive.

- Temperature range is limited in the solid core insulators.

Aerodynamic Insulators

Aerodynamic insulators feature a streamlined design that minimizes the load on power line structures during high winds. This design not only improves the stability of the power lines but also reduces the risk of mechanical failure.

They are particularly valuable in areas prone to strong winds or storms.

|

| Aerodynamic special type insulator |

Advantages of Aerodynamics Insulators

- Aerodynamic insulators are self-cleaning

- Aerodynamics insulators used in a desert area

- Aerodynamic insulators also have anti-dirt property

- This type of insulator is mechanically strong

Disadvantages of Aerodynamics Insulators

- Aerodynamic insulators are costly because of their special design.

- a lifetime of these insulators is the minimum.

- creepage distance is small.

Sub-Stations Insulators

Some types of insulators are used in the substations Including

- post-type insulators for support

- sectionalizing insulators

- bracket insulators

- tensile load insulator for diving/ pulling live parts

- operating rod insulators

- stray arm insulators

- shaft insulators

- Roofline Insulators

- Connecting Rod Insulators

Selection of Insulators

The selection of insulators is a critical parameter in power electrical systems to ensure proper insulation, safety, and efficient functioning.

We need to know about Material Properties like Dielectric Strength, thermal Stability, Mechanical strength, Environmental Conditions, Corrosion resistance, voltage ratings etc. The type of insulation and frequency response is also an important factor during the selection of insulators.

Conclusion

In conclusion, the five special types of insulators used in substations play a crucial role in ensuring the efficiency and safety of power transmission.

Each type of insulator is designed to address specific electrical and mechanical requirements, contributing to the reliable distribution of electricity across vast networks.

Frequently Asked Questions – FAQs

What is a Pin Type of Anti-Dirt Insulator?

Where are Pin Type Anti-Dirt Insulators commonly used?

What are Inclined Disc Insulators?

How are Inclined Disc Insulators installed?

Are Inclined Disc Insulators suitable for all voltage levels?

What are Deep Shed Insulators?

Where are Deep Shed Insulators typically installed?

What is a Solid Core Insulator?

What materials are commonly used to make Solid Core Insulators?

What are Aerodynamic Insulators?

Where are Aerodynamic Insulators commonly used?

Related Posts

Performance Factors of Logic Gates 2024

5 Best Anti-Tempering Components 2024

Surge Protectors Vs Power Strips

Electrical Safety Training Tips

5 Battey Backup Surge Protectors

-Electronicsinfos.png)

0 Comments

please do not insert spam links